The world of baseball cards is filled with a myriad of fascinating processes, from the initial concept and design stages to the final packaging. Among these steps, the baseball card printing and cutting process is one of the most crucial, often determining the final quality and value of the cards. This process, while seemingly straightforward, involves precision, attention to detail, and a thorough understanding of baseball card printing techniques.

Let’s delve into the step-by-step process of how manufacturers cut baseball card sheets, ensuring that collectors receive the most pristine cards possible.

1. Printing Baseball Card Sheets

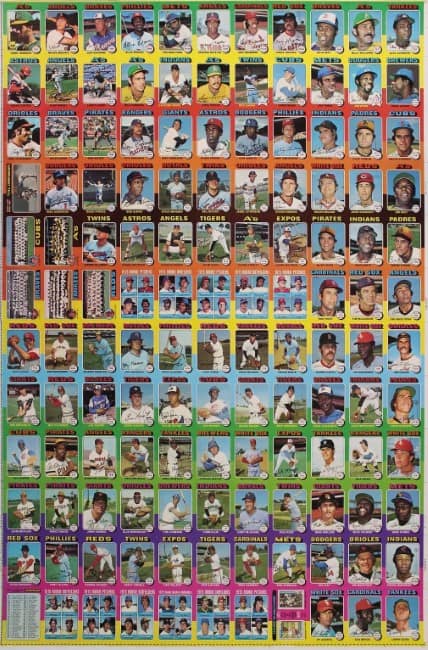

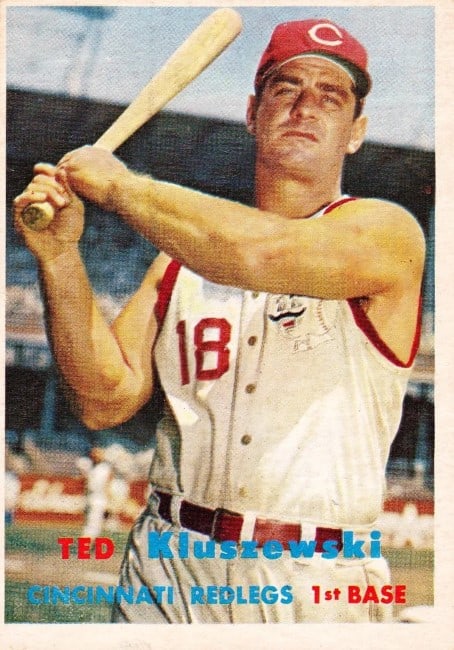

Before we can discuss the cutting process, it’s essential to understand that baseball cards start as large sheets, typically referred to as uncut sheets. These sheets contain multiple baseball cards printed in a grid pattern. Meticulous planning goes into the design of these sheets. They take into account not just the placement of each card, but also the cutting paths and margins.

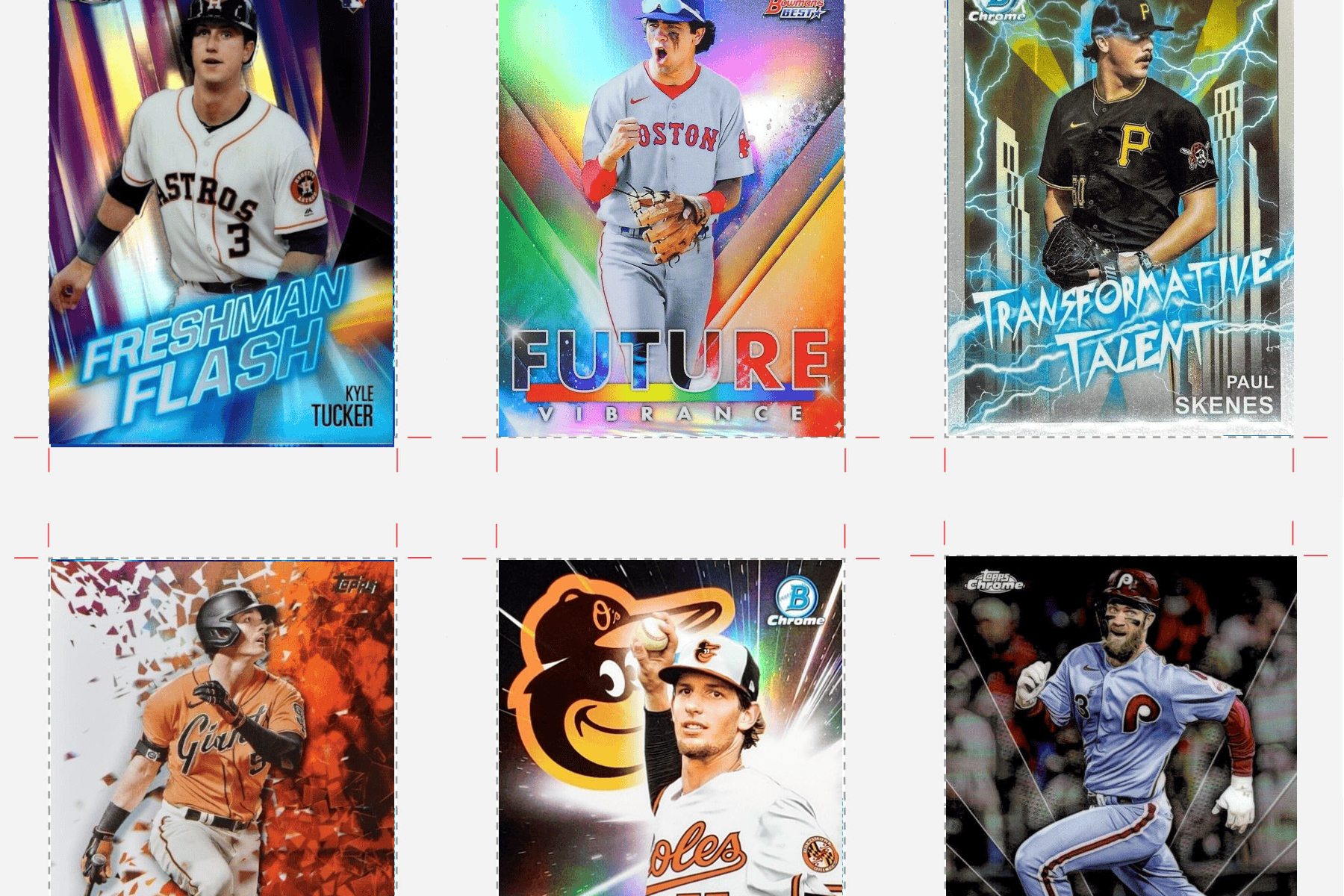

The baseball card printing process begins with the creation of high-resolution digital files. These files are used to create the printing plates. The plates are integral to offset printing, the method most commonly used in card production. Offset printing involves transferring ink from a plate to a rubber blanket, then onto the card stock. In printing, a four-color process (CMYK: cyan, magenta, yellow, and black) applies each color in layers. Separate passes can add additional foils or layers.

The card stock itself is typically a high-quality, sturdy material that can withstand handling and maintain its shape over time. Manufacturers must consider the thickness of the stock, as it can affect the cutting process and the final product.

2. Registration and Alignment

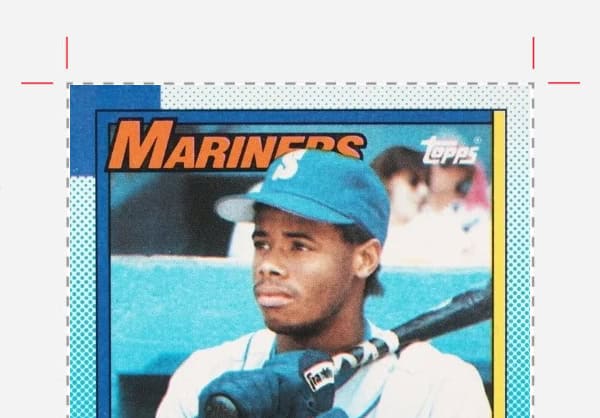

Once printed, the cards must align perfectly before cutting, a process known as “registration.” Misregistration, or misalignment, can result in off-center cards, which significantly affect both their visual appeal and market value. To achieve perfect registration, manufacturers use alignment marks—also called crop marks or registration marks—printed on the edges of the sheets. These marks guide the cutting machinery to ensure each card is cut precisely.

Advanced printing machines feature sensors that read these marks and automatically adjust the sheets’ position as they move through the production line. In some instances, skilled technicians manually adjust the sheets to correct any discrepancies. This step is critical, as even a slight misalignment—just a millimeter—can reduce a card’s desirability to collectors.

3. The Baseball Card Cutting Process

\With the sheets aligned, the next step is the actual cutting. This process typically involves a combination of guillotine cutters and die-cutting machines.

Guillotine Cutters

Guillotine cutters are large machines with straight blades, used to slice printed sheets into rows and columns. Known for their precision and efficiency, they can handle multiple sheets simultaneously.

As the sheets are fed into the cutter, each slice separates a row or column of cards. The blades are razor-sharp and carefully maintained to ensure clean, smooth cuts. A dull blade can cause rough edges, or “chipping,” which is a significant concern in card production, as it can affect both the appearance and value of the cards.

Die-Cutting Machines

Die-cutting machines are used for cards with unique shapes or rounded corners. These machines rely on custom-made metal dies, similar to cookie cutters, to stamp out each card’s shape. The dies are aligned with the printed design on the sheet and they make precise cuts. Inserts or special cards with non-standard shapes are also die-cut.

4. Baseball Card Quality Control

The cutting process is typically automated but requires constant monitoring. Technicians oversee the operation to ensure the blades remain sharp, the sheets feed correctly, and the cuts align with the registration marks. In high-volume production runs, even a small error can result in thousands of miscut cards, causing significant waste and potential delays.

After cutting, the cards undergo a rigorous quality control process. This step is critical to ensure only the best cards move to the packaging stage. Quality control inspectors check for a variety of potential issues, including:

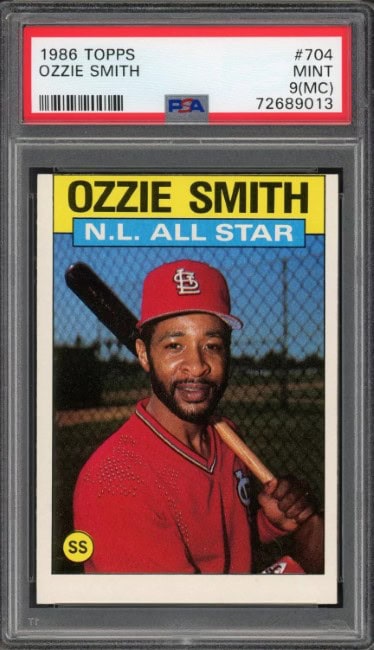

- Centering: The borders of the card must be even on all sides. Off-center cards used to be common in the hobby. However they are less valuable.

- Cutting Accuracy: Inspectors check that the cuts are clean with no rough edges or chipping. Cards with imperfections are either discarded or placed in lower-quality tiers.

- Surface Quality: The card surface is checked for any printing defects, scratches, or blemishes. Damage can significantly lower its value.

- Corners and Edges: For die-cut cards, the corners and edges must be sharp and uniform. Rounded corners, common in modern cards, must be symmetrical and free of dents or bends.

5. Packaging and Distribution

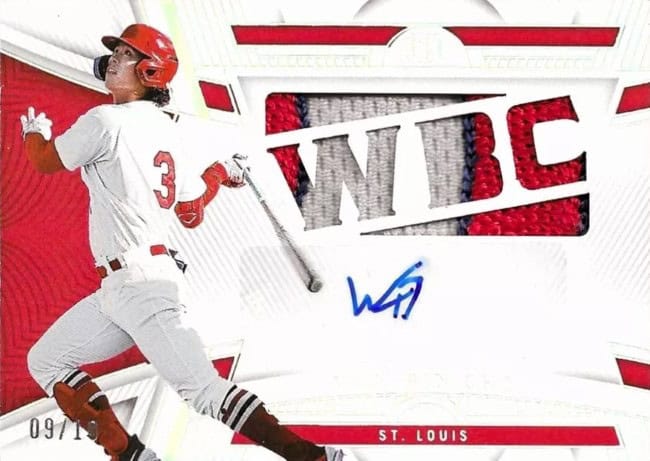

Once quality control is complete, workers sort and package the cards. They assemble complete sets, insert the cards into packs, or prepare them for special products. The packaging process ensures no damage occurs, with extra care given to valuable cards like autographs or relics.

Occasionally, manufacturers release uncut sheets as collectibles. Collectors often frame and display these sheets, offering a unique opportunity to appreciate the full art and design of a set.

The Impact of Cutting on Card Value

The precision of the cutting process has a direct impact on the value of the final product. Collectors prize cards that are well-centered with sharp edges and corners. In the grading process, companies like PSA (Professional Sports Authenticator) or BGS (Beckett Grading Services) take the quality of the cut into account, and a poorly cut card can result in a lower grade, even if the card is otherwise in mint condition.

Miscut cards, while often considered defects, can also become collectible in their own right, particularly if they show a significant portion of an adjacent card or an interesting alignment error. These anomalies, known as “freaks” or “errors,” can be highly sought after by niche collectors.

Challenges and Innovations

The cutting process, while well-established, is not without its challenges. High-speed production runs can sometimes lead to errors, and maintaining the sharpness of cutting blades over long periods is a constant concern. Additionally, the introduction of new materials, such as thicker stock or foil accents, requires adjustments to the cutting process.

In recent years, manufacturers have also explored digital printing and cutting technologies, which offer more precision and flexibility. Digital cutting machines, guided by computer programs, can create intricate designs and shapes that were previously impossible with traditional die-cutting methods. These advancements are pushing the boundaries of what is possible in card design, offering collectors new and exciting products.

Conclusion

The process of cutting baseball card sheets is a critical step in the production of baseball cards. From the initial baseball card printing and registration to the precise cutting and rigorous quality control, each stage is carefully managed to ensure that collectors receive high-quality cards. As technology continues to evolve, the cutting process is likely to become even more sophisticated, allowing for greater creativity and precision in card design. For collectors, understanding this process offers a deeper appreciation for the cards they cherish and the craftsmanship that goes into creating them.