Baseball cards have come a long way since their humble beginnings in the late 19th century. Early cards were simple, often printed on plain cardboard with little to no gloss. However, as baseball card printing technology advanced, so too did the quality of baseball cards. Basic cardboard designs have given way to glossy, foil, metallic and refractor baseball cards.

Aesthetics and rarity are two driving forces in the popularity of baseball card collecting. The transition to specialized coincided with the rise of the hobby in the 1970s and 1980s, as manufacturers sought to create more attractive and collectible products. It continued as Upper Deck emerged in 1989 with its distinctive holographic technology, and continues today as baseball card companies push the aesthetic boundaries with superfractors.

Baseball Card Printing

At the heart of any high-gloss baseball card is its finish. Unlike the matte or semi-gloss cards of yesteryear, high-gloss cards boast a reflective surface that enhances colors, images, and overall visual appeal. A combination of materials and techniques creates this effect.

Cardstock

The foundation of any baseball card, the cardstock, plays a crucial role in determining the final glossiness. The card is typically made from recycled paper pulp but it’s the surface coating that imparts the desired shine. This coating can be applied in various ways, each with its own unique properties.

Offset Printing

The most common method for printing baseball cards, offset printing involves transferring ink from an image carrier (plate) to a rubber blanket, and then onto the cardstock. Then, to achieve a high-gloss finish, the ink used is specifically formulated with resins and pigments that create a reflective surface when dry.

UV Coating

A popular technique to enhance glossiness, UV coating involves applying a liquid polymer to the card’s surface and curing it with ultraviolet light. This process creates a durable, protective layer that also imparts a high degree of shine. UV coatings can be applied in various thicknesses, allowing manufacturers to control the level of gloss.

Foiling

For an extra touch of luxury, some high-gloss cards incorporate foil stamping. This process involves applying a thin layer of metallic foil to the card’s surface using heat and pressure. The foil can be embossed for added texture, creating a truly eye-catching effect.

Embellishments

Beyond the basic gloss finish, manufacturers often employ additional embellishments to elevate the card’s visual appeal. These can include holographic elements, lenticular images that appear to move, and even textured surfaces. These embellishments add depth and complexity to the card, making it a truly unique collector’s item.

Types of Baseball Card Finishes

The original style of baseball card printing is alive and well in sets like Topps Heritage and Allen & Ginter. However, advanced printing techniques have become the norm for baseball cards, and nearly all sets have at least some modern techniques in their sets.

Glossy Baseball Cards

Glossy baseball cards are characterized by their shiny, reflective surface. This finish enhances the colors and images, making them more visually appealing. Think about your options when you’re buying house paint – some paints are glossy while others are flat, even within the same brand and color palette. The final effect is determined by what you’re painting and the type of paint you’re using. Baseball card printing is similar.

How Glossy Baseball Cards Are Made

The glossiness of a baseball card comes from a combination of factors:

- Cardstock is the base material of a baseball card. The core is typically recycled paper pulp, but it’s the surface coating that imparts the shine.

- Printing inks with reflective properties are used to print the images and text.

- Glossy coatings are applied over the printed card to enhance the shine.

Determining the exact date of the first glossy baseball card is difficult due to the gradual evolution of card production techniques. Gloss finishes were a gradual evolution rather than a single moment. However, as printing technology advanced in the mid-20th century, baseball card companies began to appear glossy due to better inks and paper coatings. By the 1980s, higher gloss was introduced, and today it is nearly the standard.

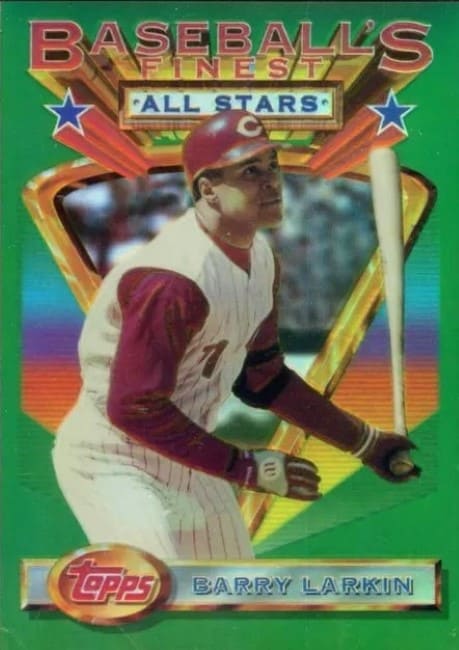

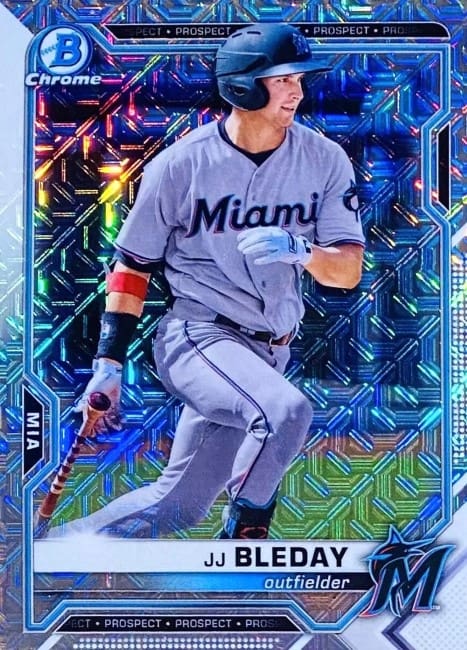

Refractor Baseball Cards

Refractor baseball cards are a type of high-gloss card that features a prismatic or rainbow-like effect. This mesmerizing visual is achieved through a specialized printing process that involves applying a thin layer of acrylic or plastic over the card’s image. Thus, as light hits the card, it refracts, creating a spectrum of colors that shift and change depending on the viewer’s angle.

The creation of refractor baseball cards involves meticulous attention to detail. The acrylic or plastic layer must be applied evenly and with precise thickness to achieve the desired refractive effect. Additionally, the underlying image must be of high quality to ensure that the refracted colors enhance rather than obscure the details.

Due to the additional production steps involved, refractor baseball cards are typically produced in limited quantities, making them highly sought after by collectors. Therefore, their rarity and unique visual appeal contribute to their elevated value in the marketplace.

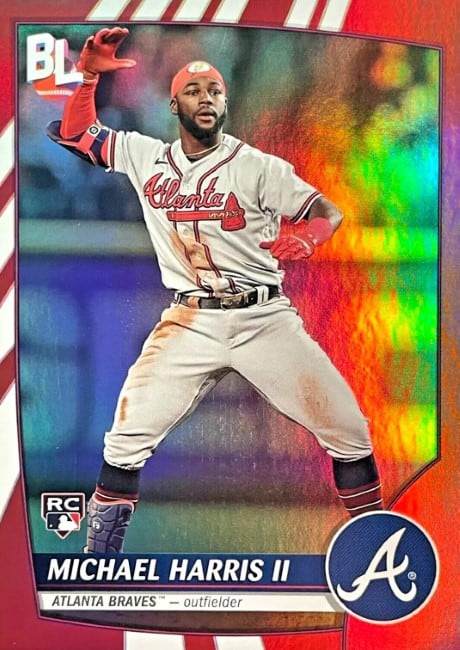

Foil Baseball Cards

Foil cards, as the name suggests, incorporate metallic foil into their design. This can be done in various ways, including:

- Full Foil: The entire card is covered in a layer of metallic foil, creating a mirror-like effect.

- Spot Foil: Foil is applied to specific elements of the card, such as the player’s name, logo, or team name, adding a touch of elegance.

- Embossed Foil: The foil is applied and then embossed to create a raised, textured effect, enhancing the card’s dimensionality.

The process of creating foil cards involves sophisticated machinery that applies the foil with precision. While the type of foil used can vary, from gold and silver to more exotic options like rainbow or holographic foil, the concept is the same.

Generally, like refractor baseball cards, foil cards are often produced in limited quantities, contributing to their desirability among collectors. Thus, the combination of metallic shine and tactile appeal makes them a popular choice for those seeking unique and eye-catching cards.

Rainbow foil is a type of foil that produces a multicolored, iridescent effect when applied to a surface. It’s created through a specialized process that involves embedding tiny prisms or diffraction gratings into the foil’s surface. Then, these microstructures interact with light, causing it to disperse into a spectrum of colors.

How Rainbow Foil is Made

The exact process for creating rainbow foil is proprietary information held by manufacturers. However, it generally involves:

- Substrate preparation: The cardboard base material is prepared for the foil coating.

- Prism or grating application: Tiny prisms or diffraction gratings are embedded into the foil’s surface.

- Protective coating: A protective layer is applied to preserve the foil’s integrity.

Types of Rainbow Foil

There are several types of rainbow foil available, each with its own unique characteristics:

- Holofoil: This type of foil creates a holographic effect, with images appearing to change as the viewing angle shifts.

- Iridescent foil: Produces a soft, shimmering effect with a subtle color shift.

- Spectrum foil: Offers a wider range of colors and a more pronounced rainbow effect.

Rainbow foil is a popular choice for adding a touch of magic and wonder to any project. Its versatility and stunning visual appeal make it a favorite among designers and consumers alike.

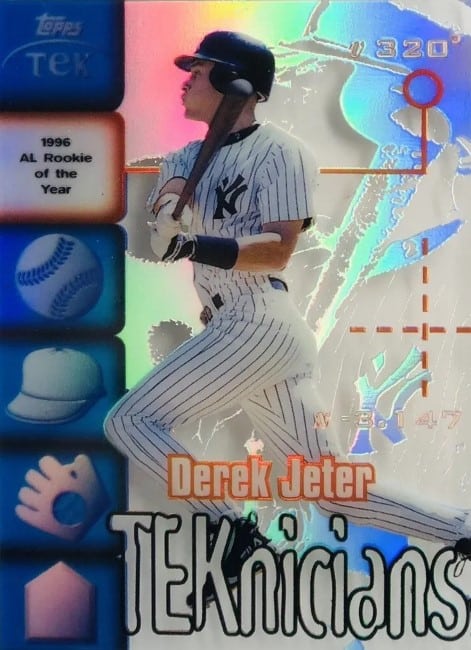

Clear Baseball Cards

Clear baseball cards have become increasingly popular in recent years, offering a unique and visually striking take on the traditional trading card. These cards feature a transparent background, allowing the card’s design and player image to stand out in a captivating way.

How Clear Baseball Cards Are Made

The process for creating clear baseball cards involves several steps:

- Card Base Creation: A clear plastic sheet is used as the base for the card.

- Image Printing: The player image, team logo, and other card details are printed onto the plastic sheet using specialized inks.

- Protective Coating: A protective layer is often applied to prevent scratches and damage.

- Cutting and Packaging: The card is cut to the standard baseball card size and packaged for distribution.

Several card manufacturers have released clear card sets, including Topps Clearly Authentic – known for its encased autographs – Topps High Tek, Leaf Trinity Clear Autographs and Panini Chronicles Clear Vision.

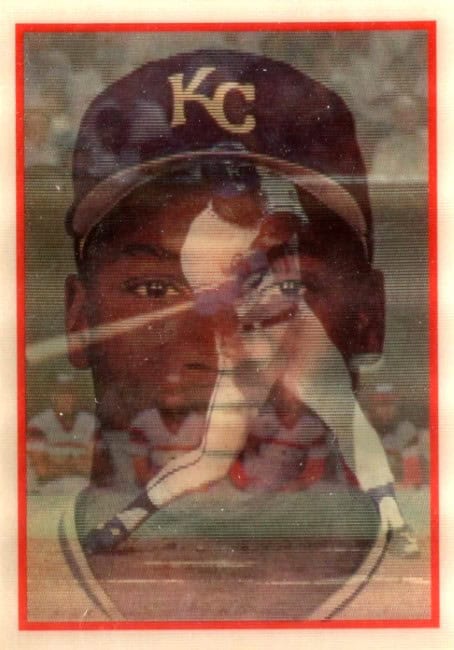

Lenticular (3D)

Lenticular baseball cards – also known as 3D cards – create the illusion of depth, motion, or even multiple images, depending on the viewer’s perspective, on the same surface. They were trendy in the 1980s to 1990s but are rarely used today.

How Lenticular Cards Work

A lenticular lens is a sheet of plastic with tiny cylindrical lenses arranged in parallel rows. Two or more images are printed on the card, and the lens acts as a prism, separating the images and presenting them to the viewer at different angles. Thus, this creates the illusion of movement or depth.

At a casual glance, lenticular baseball cards can appear jumbled or lo-fi. However, it’s the movement of the viewer that makes the card images “move.”

Sportflics was the most popular lenticular baseball card company, hitting its dominance in the late 1980s. Kellogg’s also produced series of lenticular baseball cards. More recently, Topps and Upper Deck have been experimenting with the technology with “3D” parallels of their popular cards.

Lenticular cards can be more expensive to produce than traditional cards due to the specialized printing and lensing processes. Additionally, the quality of the lenticular effect can vary, with some cards offering a more pronounced and impressive animation than others.

Despite these challenges, lenticular baseball cards continue to captivate collectors with their unique and interactive nature.

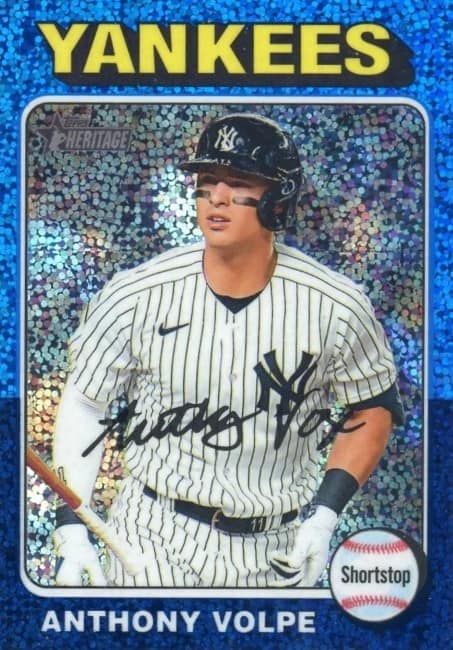

Glitter

Glitter cards add a touch of sparkle and fun to the collecting experience. Here’s a simplified breakdown of the process. Glitter is applied to the cardstock in one of several ways:

- Direct application: Wet adhesive or glue is applied to the card surface, and then glitter is sprinkled onto the wet surface. It’s a lot like a school art project!

- Foil stamping: Glitter is embedded in foil and then stamped directly onto the card.

- Ink with glitter: Some inks contain glitter particles that are transferred to the card during printing, like very sophisticated glitter ink pens or paints.

Embossed & Debossed

Embossing creates a raised image on a baseball card’s surface, and debossing does the opposite – it creates a sunken image. Coins are commonly embossed, creating a subtle raised image on the surface of the coin.

Popular baseball card sets like 1965 Topps Embossed have proven popular, although embossing and debossing is more typically used as a technique to emphasize a foil application than to create an entire card.

Refractor, Foil & Parallel Rarities

In the early days, baseball card sets were simple: There was a set number of cards and a completionist would own one of each. Even for large sets, like the 910-card 1992 Score set, it feels attainable.

Now, the most popular baseball cards sets feature dozens of parallels. These parallels have differing rarities (and are often serial numbered); in addition, some parallels are only available in certain types of packs, boxes or retail stores. (For example, in 2024 Topps Heritage, gold foilboards are Walmart exclusives while platinum foilboards and red border cards are exclusive to Target, and aqua parallels are exclusive to Fanatics.)

In 2024 Topps flagship product, there are 700 base cards across two series. There are 32 parallels of those base cards (21 of which are serial numbered). The parallels range from easier to find varieties like rainbow foil and yellow foil (1:10 packs) to a platinum 1/1. Popular parallels include the Mother’s Day (hot pink) and Father’s Day (powder blue) varieties, which are both numbered to /50. The holiday-themed parallels (flowers, birds, waves, etc.) are also highly sought after.

Care & Storage of High-Finish Baseball Cards

For collectors, high-gloss, foil and refractor baseball cards offer a unique aesthetic experience. The shimmering surface enhances the visual appeal of the card, making it a pleasure to handle and display. Moreover, the finish can help to protect the card from damage, as it creates a barrier between the card and the environment.

However, high-finish cards also present some challenges for collectors. The fingerprints and smudges that are inevitable with handling can be more noticeable on glossy cards, detracting from their appearance.

The glossy baseball card surface can be susceptible to scratches, which can significantly impact the card’s value. Some sets are known for printing imperfections that create lines in the surface of the card’s coating. Finally, the edges are susceptible to chipping, which can appear obvious with certain surfaces or colors.

Conclusion

The introduction of refractors and foil cards has significantly influenced the baseball card hobby. These special card variations have added a new level of excitement and collectability, attracting both seasoned collectors and newcomers alike. The chase for rare and valuable refractors and foil cards has become a driving force for many collectors, fueling the secondary market and creating opportunities for profit.

Moreover, these card variations have pushed the boundaries of card design, inspiring manufacturers to experiment with new materials and techniques. As a result, the baseball card market has become increasingly diverse and visually appealing, catering to a wide range of collector preferences.