Your cart is currently empty!

As environmental awareness grows, many industries are being scrutinized for their environmental impact and sustainability practices. Card collecting, a pastime and business for millions worldwide, is no exception. In a hobby traditionally reliant on paper and plastics, discussions around its ecological footprint have begun to emerge. This article explores the environmental impact of card collecting, focusing on materials used, production methods, recycling practices, and efforts toward reducing the hobby’s carbon footprint.

The Role of Paper in Card Collecting

Paper Usage in Trading Cards

The primary material in trading cards is paper, typically derived from wood pulp. Modern baseball cards are usually printed on thick cardstock, which often contains multiple layers, including a base layer of paper and various coatings for durability and aesthetic appeal.

While paper itself is a biodegradable material, the large-scale consumption of wood products has significant environmental consequences. Deforestation to meet the demand for paper contributes to habitat destruction, biodiversity loss, and an increase in carbon emissions, as forests act as vital carbon sinks. In addition, the production of paper involves energy-intensive processes, including pulping, bleaching, and coating, all of which contribute to environmental degradation.

Sustainable Paper Sources

Some companies in the collectibles industry are beginning to shift toward more sustainable practices, such as sourcing paper from Forest Stewardship Council (FSC)-certified forests. FSC certification ensures that the paper comes from responsibly managed forests that take into account environmental and social concerns. However, the adoption of such practices is not yet widespread, and many card manufacturers still rely on conventional paper sources.

Production Methods: Energy, Water, and Chemicals

Energy Consumption

The production of trading cards requires significant amounts of energy. From the creation of the paper itself to the printing, cutting, packaging, and shipping of cards, the process is energy-intensive. Much of the energy used in these processes comes from non-renewable sources such as coal and natural gas, contributing to greenhouse gas emissions and climate change.

Water Usage

Water is another resource heavily consumed in card production, particularly during the paper-making process. The paper industry is known to be one of the largest consumers of fresh water globally. Efforts to reduce water usage have been made in certain sectors, but the overall environmental footprint remains significant.

Chemicals in Baseball Card Production

Beyond energy and water, the production of trading cards often involves the use of chemicals, particularly in the inks and coatings applied to cards. Traditional inks contain volatile organic compounds (VOCs), which can contribute to air pollution when released into the atmosphere. Many card manufacturers are transitioning to low-VOC or soy-based inks as part of broader sustainability efforts, but not all companies have adopted these greener alternatives.

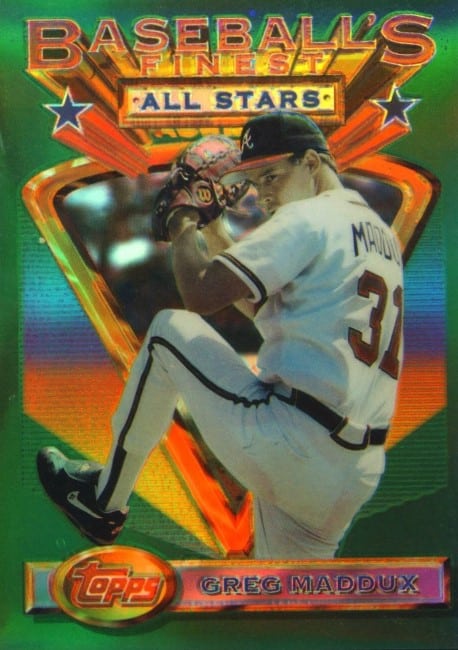

The coatings applied to trading cards, including UV coatings, laminates, and gloss finishes, can also present environmental challenges. These materials make recycling more difficult and can prevent the cards from biodegrading over time.

Recycling and Waste in the Hobby

Recycling Baseball Cards

One of the major issues with card collecting from an environmental perspective is the recyclability of the cards themselves. While pure paper is relatively easy to recycle, modern baseball cards are often coated with plastics or other non-biodegradable substances that complicate the recycling process. In addition, cards that are laminated or feature metallic foils are difficult to break down into reusable materials.

Glossy Baseball Cards

Glossy cards are usually made of a paper base that is coated with one or more layers of synthetic materials. These are applied to cards to give them a high-gloss finish. UV coatings are usually made from plastic polymers that harden when exposed to ultraviolet light.

The recyclability of glossy cards depends largely on the type of coating and how integrated it is with the paper. Even if a glossy card has a paper core, the plastic layer often prevents it from being processed in standard paper recycling streams. Facilities that accept mixed paper waste typically reject items with heavy coatings because they can clog machinery or degrade the quality of recycled paper.

Some glossy coatings are light enough that they may not interfere significantly with recycling processes. Cards with very thin or water-based coatings stand a better chance of being recycled.

Foil Baseball Cards

Foil baseball cards and similar items are typically made from aluminum or metalized plastic films. Aluminum is theoretically recyclable, but when it is used as a thin layer on cards, it often becomes contaminated with adhesives, coatings, or laminates that make it difficult for traditional recycling facilities to process.

Many recycling plants cannot process small, thin layers of foil as they get shredded during sorting or are missed entirely. If the foil is attached to paper or other materials, it is difficult to separate without specialized equipment.

Glitter Baseball Cards

Glitter, often used on cards and other products for a sparkling effect, is generally made from microplastics, tiny reflective particles of plastic, metal, or mica. It is essentially a microplastic, and microplastics are notorious for polluting waterways and oceans. Because of their small size, they often escape filtering processes at recycling and waste management plants. The small size and mixed material composition of glitter make it impractical to separate and recycle. In mixed waste streams, glitter can contaminate paper or plastic recycling processes, leading to lower quality recycled materials.

Long-Term Waste

Cards that end up in landfills contribute to long-term waste. Although cards are not a significant portion of the overall waste stream, they are part of a larger problem of disposable culture. Few collectors actively recycle their cards, and manufacturers have not yet implemented widespread programs to encourage the recycling of cards.

Packaging Waste

Another significant contributor to waste in the card industry is the packaging. Trading cards are typically sold in plastic wrappers, cardboard boxes, and plastic cases, all of which contribute to environmental waste. Plastic packaging, in particular, has become a growing concern. This is due to its persistence in the environment and the fact that only a small percentage of plastics are recycled.

Some companies have started to explore more sustainable packaging options. For example, biodegradable or recyclable packaging materials could help reduce the environmental impact of card collecting. However, these innovations remain niche and have yet to be adopted at scale across the industry.

Zero Carbon and Other Sustainability Efforts

Efforts Toward Carbon Neutrality

With increasing pressure to address climate change, some industries have begun to focus on reducing or offsetting their carbon emissions. The sports card industry, while slower to adapt, is starting to see companies explore the possibility of carbon-neutral production.

A few manufacturers have made strides toward reducing their carbon footprints by using renewable energy sources for their production facilities, investing in energy-efficient technologies, and purchasing carbon offsets. Carbon offsets allow companies to compensate for their greenhouse gas emissions by funding projects that reduce or capture carbon elsewhere. These funds go toward reforestation or renewable energy initiatives.

One notable example is Topps, which has begun making small steps toward more sustainable production. The company has explored eco-friendly materials for packaging and experimented with digital card platforms, which significantly reduces physical waste. While full carbon neutrality is a long way off, these efforts indicate that the card industry is at least beginning to acknowledge the issue.

The Role of Digital Cards

Digital baseball card platforms, such as Topps Bunt, offer an intriguing solution to the environmental challenges of traditional card collecting. These platforms allow collectors to purchase and trade cards that exist entirely in digital form, eliminating the need for physical production, packaging, and shipping.

While digital cards do not have the same tactile appeal as physical cards, they present a significant reduction in the environmental impact of card collecting. Digital platforms produce no paper waste, require no plastic packaging, and have a lower carbon footprint overall. However, the servers and data centers that support these platforms still consume energy, much of which comes from non-renewable sources, meaning that even digital collectibles are not entirely carbon-neutral.

Moving Toward a More Sustainable Future

Consumer Demand for Green Practices

One of the driving forces behind sustainability efforts in many industries is consumer demand. As more collectors become aware of the environmental impact of their hobby, they may begin to demand more sustainable products from card manufacturers. This shift in consumer preferences could encourage companies to adopt greener practices, such as using recycled materials, reducing packaging waste, and investing in renewable energy sources.

Potential Innovations

Innovations in materials science and production methods could help reduce the environmental impact of card collecting. For example, the development of fully recyclable or biodegradable card materials would be a significant step forward. Similarly, advances in printing technology could allow for more energy-efficient production processes.

Some companies are experimenting with plant-based plastics and other sustainable materials that could replace traditional coatings and laminates. However, these innovations are still in their early stages, and widespread adoption remains a challenge.

Industry-Wide Initiatives

To make meaningful progress, industry-wide initiatives may be necessary. The card collecting industry could benefit from standardized sustainability certifications, similar to those found in other sectors such as food and clothing. For example, a certification program could ensure that cards are produced using sustainably sourced materials, low-impact production methods, and recyclable packaging.

Additionally, partnerships between card manufacturers and environmental organizations could help raise awareness and promote greener practices within the industry. Collaborative efforts could also focus on improving recycling infrastructure, making it easier for collectors to recycle their cards and packaging.

Conclusion

Card collecting, like many hobbies, has an environmental footprint that cannot be ignored. From the paper and chemicals used in card production to the waste generated by packaging and disposal, the hobby has a significant impact on the environment. However, there are opportunities for the industry to reduce the environmental impact of card collecting through more sustainable practices, including the use of FSC-certified paper, low-VOC inks, biodegradable packaging, and digital card platforms.

As consumer demand for greener products grows, manufacturers have the opportunity to lead the way in making card collecting a more sustainable hobby. By investing in innovative materials, energy-efficient production methods, and industry-wide initiatives, the card industry can take meaningful steps toward reducing its environmental impact and preserving the hobby for future generations.

Tags:

Share: